Ultrasonic welding is the fastest and most cost effective method used today to join and assemble plastic parts and non-ferrous metals. Ultrasonic welding is cost effective and a green technology. Ultrasonic welding eliminates the need to use

fasteners, glues and/or solvents.

Ultrasonic Welding can be used to join all rigid thermoplastics, synthetic fabrics and films. Ultrasonic welding uses an

acoustic tool called an ultrasonic horn made to match your parts design. Ultrasonic Welding is converted to heat through

friction that melts the plastic or metal. The main components of an ultrasonic welding system are the actuator and power

supply, converter/booster & ultrasonic horn called the stack, part holding weld fixture/jig.

Material selection, Surface contact, Field of weld, Joint design, and Welding amplitude are all factors in determining the

proper booster and horn design for any given application. Understanding the following principles and your application

requirements will shed much light on this technology.

Methods applied in ultrasonic welding includes butt welding, riveting, scraf welding, spot welding, shaping,and fusing

cutting.

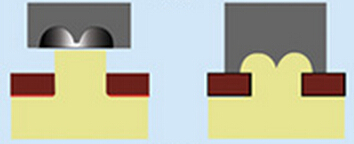

1. Butt Welding

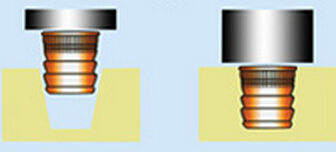

2. Riveting

3. Scarf Welding

4. Spot Welding

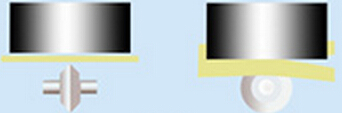

5. Shaping

6. Fusing Cutting

Previous:The Working Principle for Ultrasonic Sewing Machine

Next:Common Failure and Trouble-shooting for Ultrasonic Sewing Machine