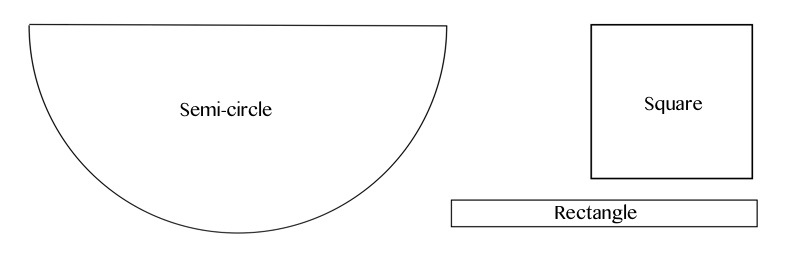

This post will discuss the two basic panel shapes you need to understand if you are a designer or a patternmaker. By panel, I mean a distinct shape of fabric. For the purposes of pleating, panels can be either semi-circles or squares/rectangles. (For you geeks out there that like technical definitions the second shape is a quadrilateral with right angles.)

Semi-circle:

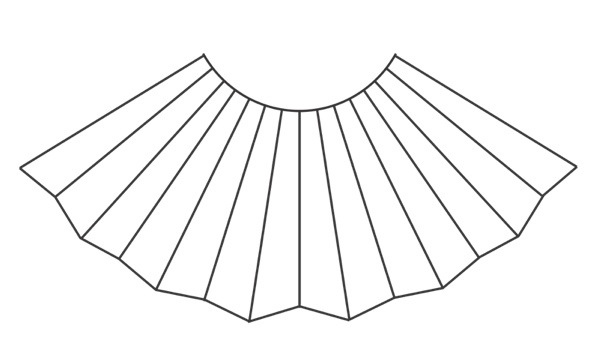

What you need to know regarding this shape is that the fabric needs to be cut into a semi-circle if you require sunburst pleating. Sunburst pleating is a type of pleating that emanates out from one point – like the rays of the sun – hence the term sunburst or sunray pleating. Notice how the size of the pleat gets smaller as it approaches the center of the circle. This can only be done by with this shape, and it must be cut into this shape before pleating. See some examples of sunburst below:

Square & Rectangular Panels:

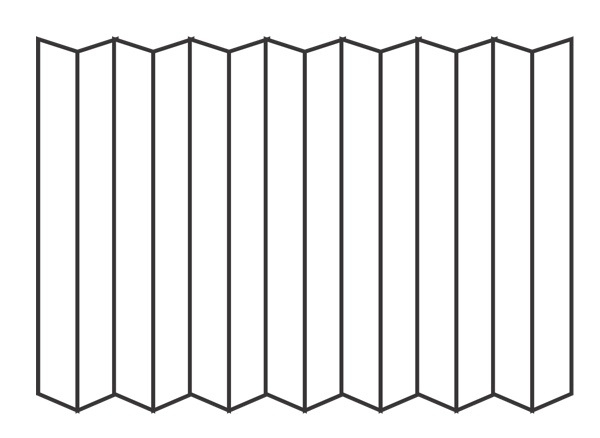

Square and rectangular panels are a bit more straight forward than the circular shaped panel. First, the size of the pleat is the same along the distance of the pleat. So the size at the top of the dress and the size at the bottom of the dress (or whatever you are sewing) will be the same. The second thing to note is that you are pleating along one grain line as opposed to sunburst pleating which is pleated across all three grain lines: straight grain, cross grain and bias grain.

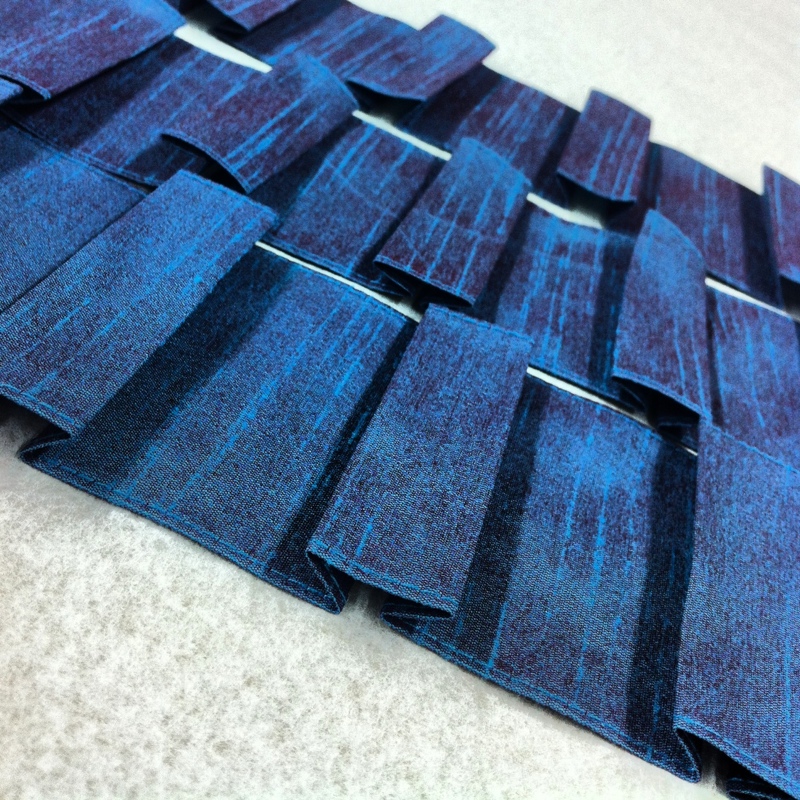

Below you will see an illustration of a square panel and a pleated leather skin. Notice how the size of the pleat does not change throughout the pleat.

The reason I am making a distinction between square and rectangular pleating is so you will have a better understanding of trims and ruffles. Whether you need to add a pleated trim to your dress or make a pleated bed skirt around your bed, the principle is the same. You need a long rectangular shape. Sometimes that rectangle can be 50 inches and sometimes that rectangle can be as long as 50 yards.

Below are some examples of custom pleated trims that we have made. The blue fabric was an iridescent silk, pleated in a box pleat that was to be appliquéd to garments. The grey fabric was a polyester taffeta made from Trevira fiber (our favorite). We made a side pleated ruffle with the Trevira fabric for a custom pleated drapery project.

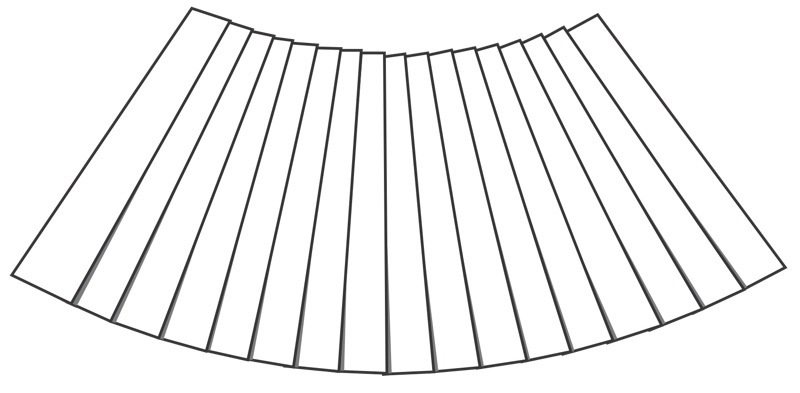

There is one more panel shape you need to understand regarding the pleating of fabric. This shape is sort of an amalgamation between the square panel and the half circle panel. It is a curved straight panel. (See picture below.)

I know what you’re thinking…WHAT????

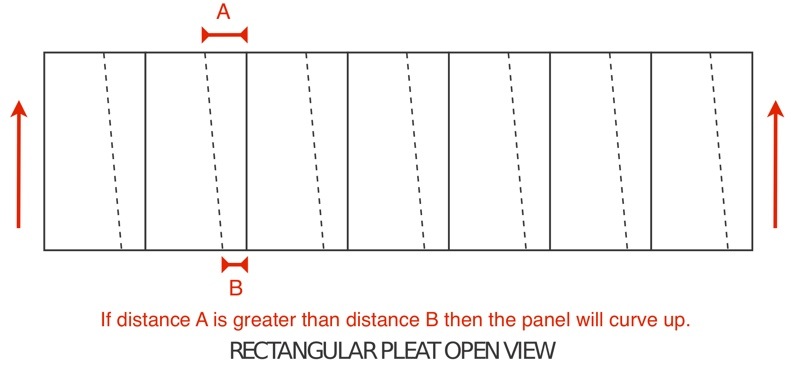

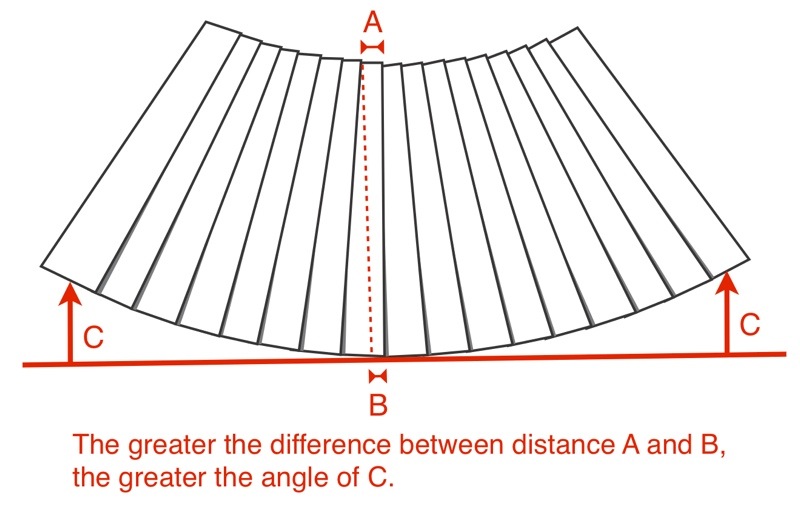

Allow me to explain. If you take a square or rectangular panel and fold it slightly deeper(or more) along one side of the panel, the opposite side will begin to curve up.

The curvature (C) of the pleated panel will increase the deeper the fold is on the top (A).

Now looking at this picture you might think, what’s the big deal? This looks just like sunburst. Yes, it sorta does but sunburst is pleated along all 3 grainlines whereas this panel is only pleated along one grain line.

There are several variables you need to consider when deciding when to use this panel shape for your pleating project. I’ll start with the technical reasons, because ultimately they dictate procedure.

Technical Reasons:

1. You want to pleat along one grain line so you can have a folded hem on your garment before you pleat.

2. You don’t want the fabric to stretch along the bias as it would if it is sunburst pleating (half circle panel).

Aesthetic Reason:

3. You like the way it looks because you can create an Aline effect. The amount of Aline can be controlled by amount of depth (or curvature) you give to the pleating panel.

4. You have a striped or checkered fabric that you do not want to distort as you would in sunburst pleating. For example, below is a photo of a wool plaid fabric on our cutting table.

Below is a photo of the wool plaid fabric pleated in our curved pattern. Notice how the checks all line up.

Below is a photo of the same fabric pleated in a sunburst half circle panel. Again, notice the checks in the fabric. Since you are pleating along all three grain lines the pattern of the fabric will be distorted.

Previous:Basic Knowledge for Accordion Pleat, Side Pleat and Box Pleat